399

KID

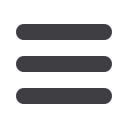

Black

Fuchsia

Oxford

Grey

Sky

Blue

White

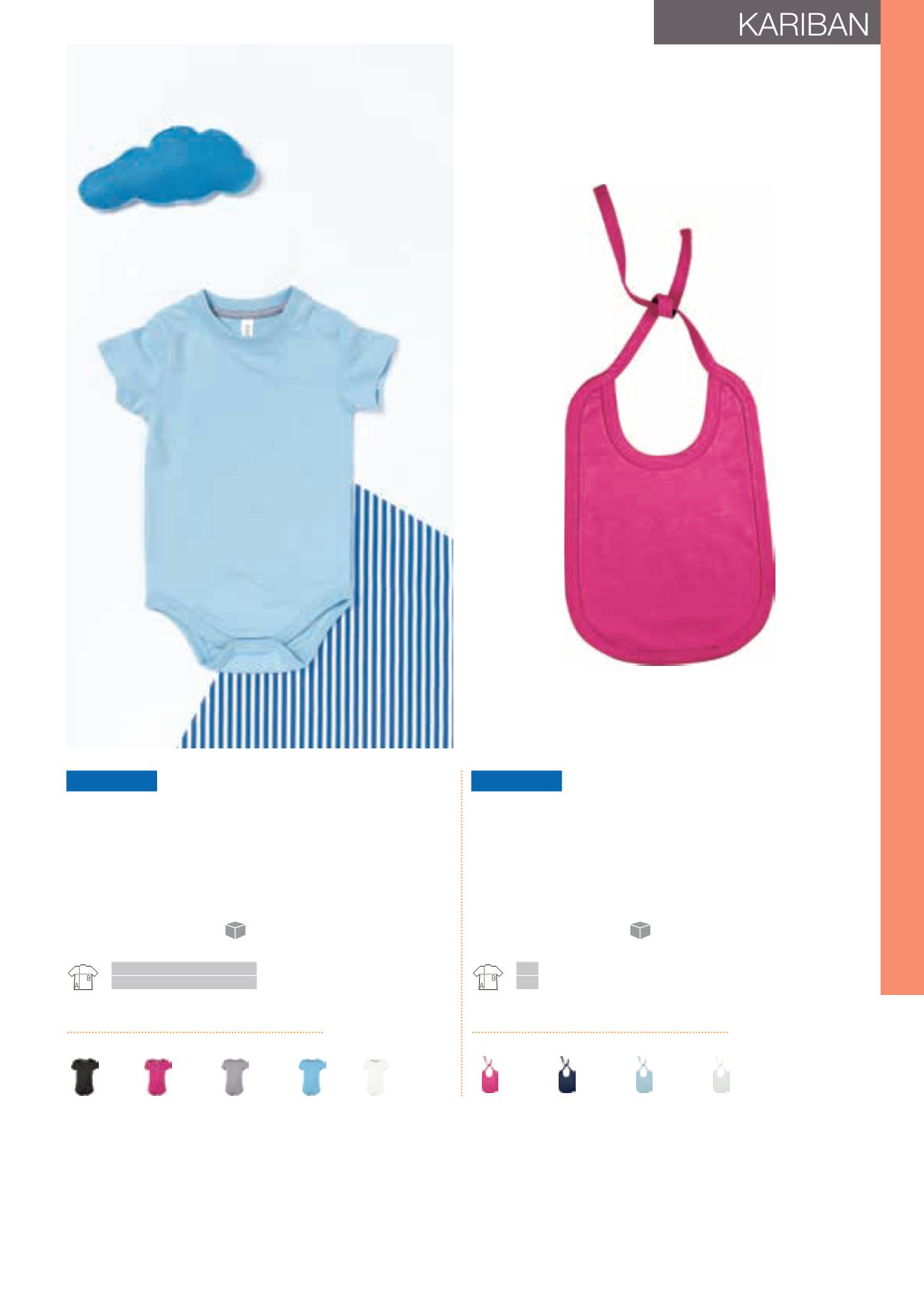

Fuchsia

Navy

Sky

Blue

White

SIZES

A/B

3M 6M 9M 12M 18M 24M

36/20 37/21 39/23 40/24 42/25 44/26

KA831

BABIES’ SHORT SLEEVE BODYSUIT

100% enzyme-washed cotton jersey • Crew neck with 2 shoulder press studs

• 3 press studs at bottom • Ribbed neck and leg openings

5 Colours

3M-24M

180 g/m

2

3M-24M

3M-24M: 50;

SIZES

A/B

U

23/22

KA832

BABIES’ BIB

100% enzyme-washed cotton jersey • Reversible • String tie fastening • Double

fabric • Bound edges • Dimensions: 22x23 cm

4 Colours

U

180 g/m

2

U

U: 100;